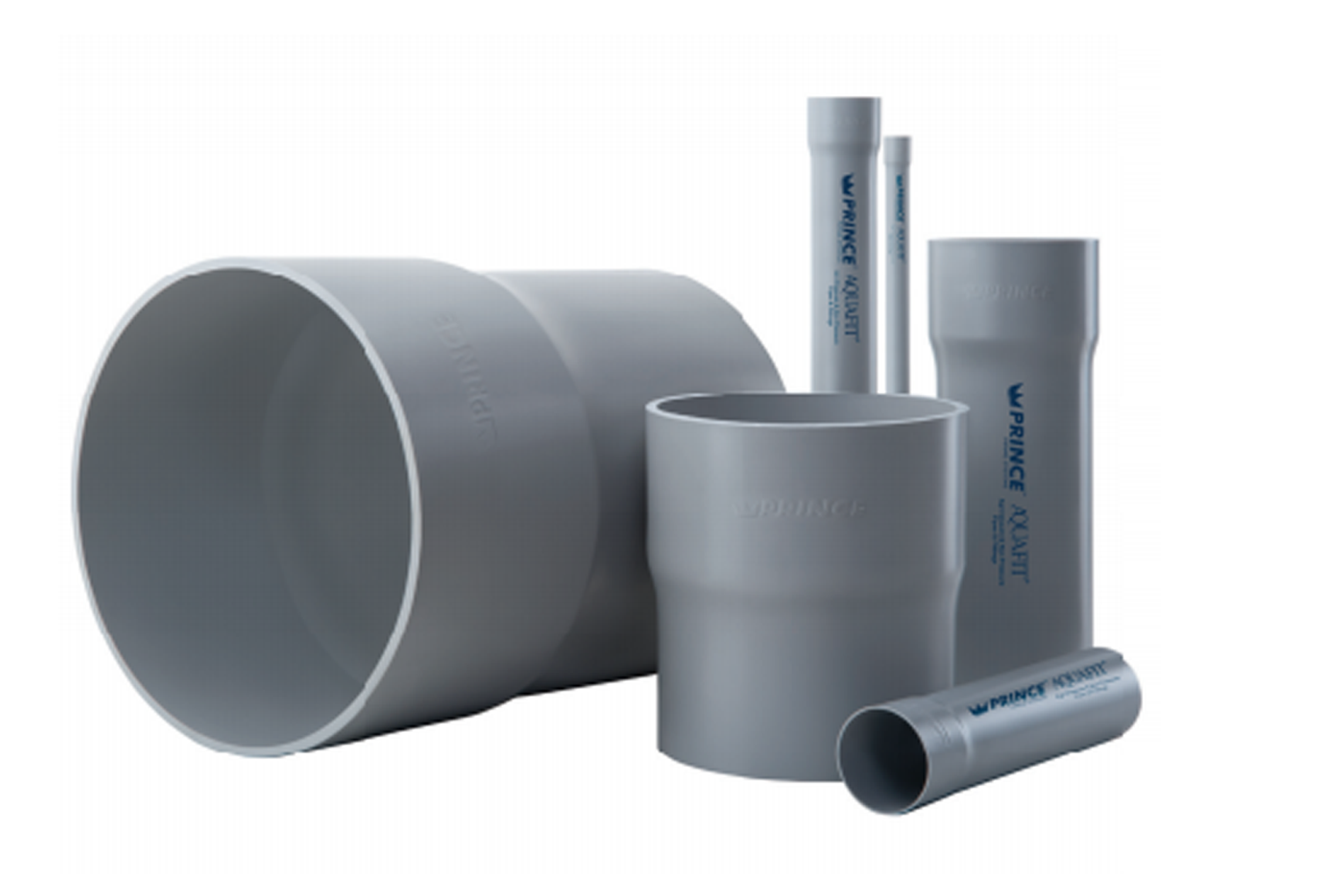

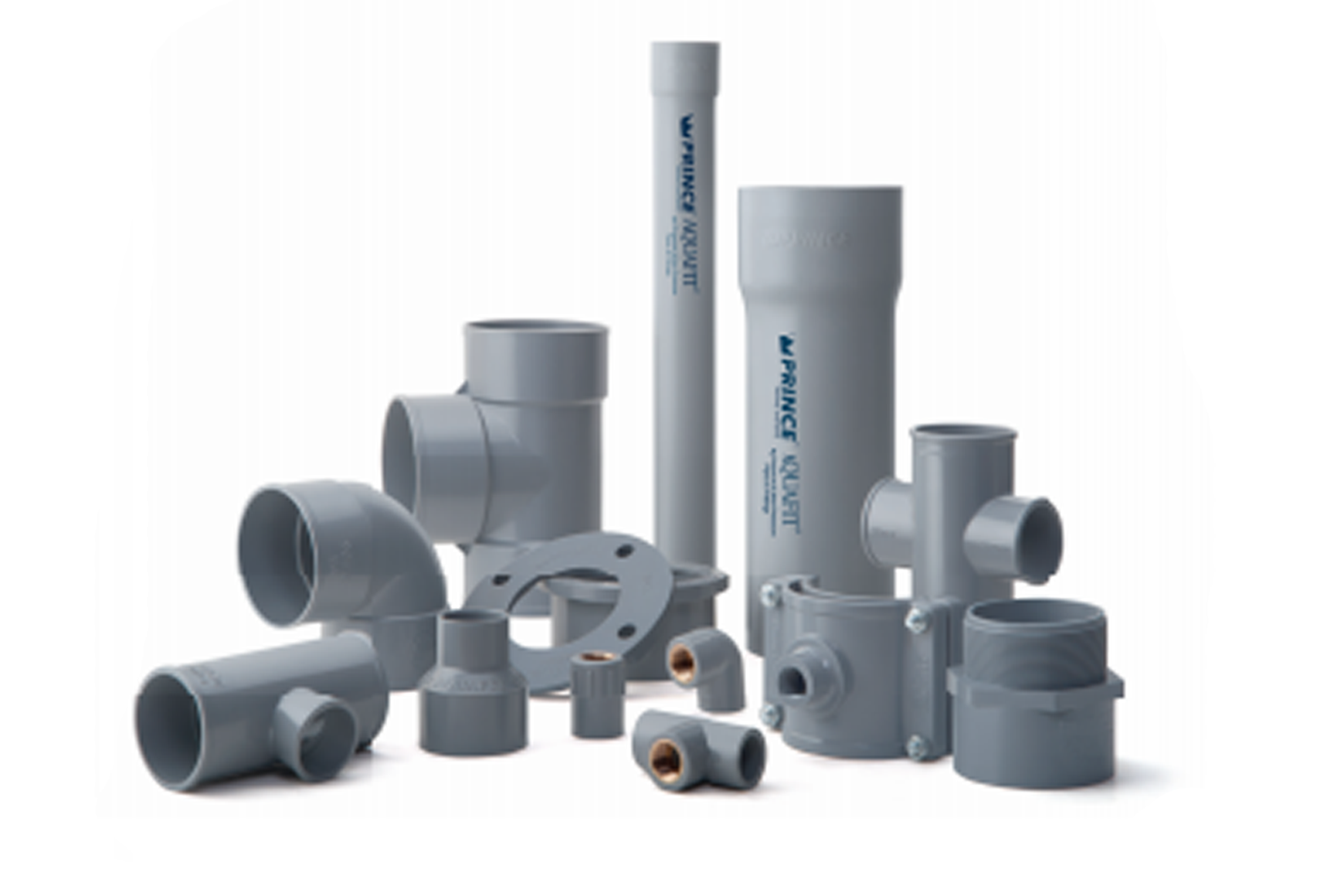

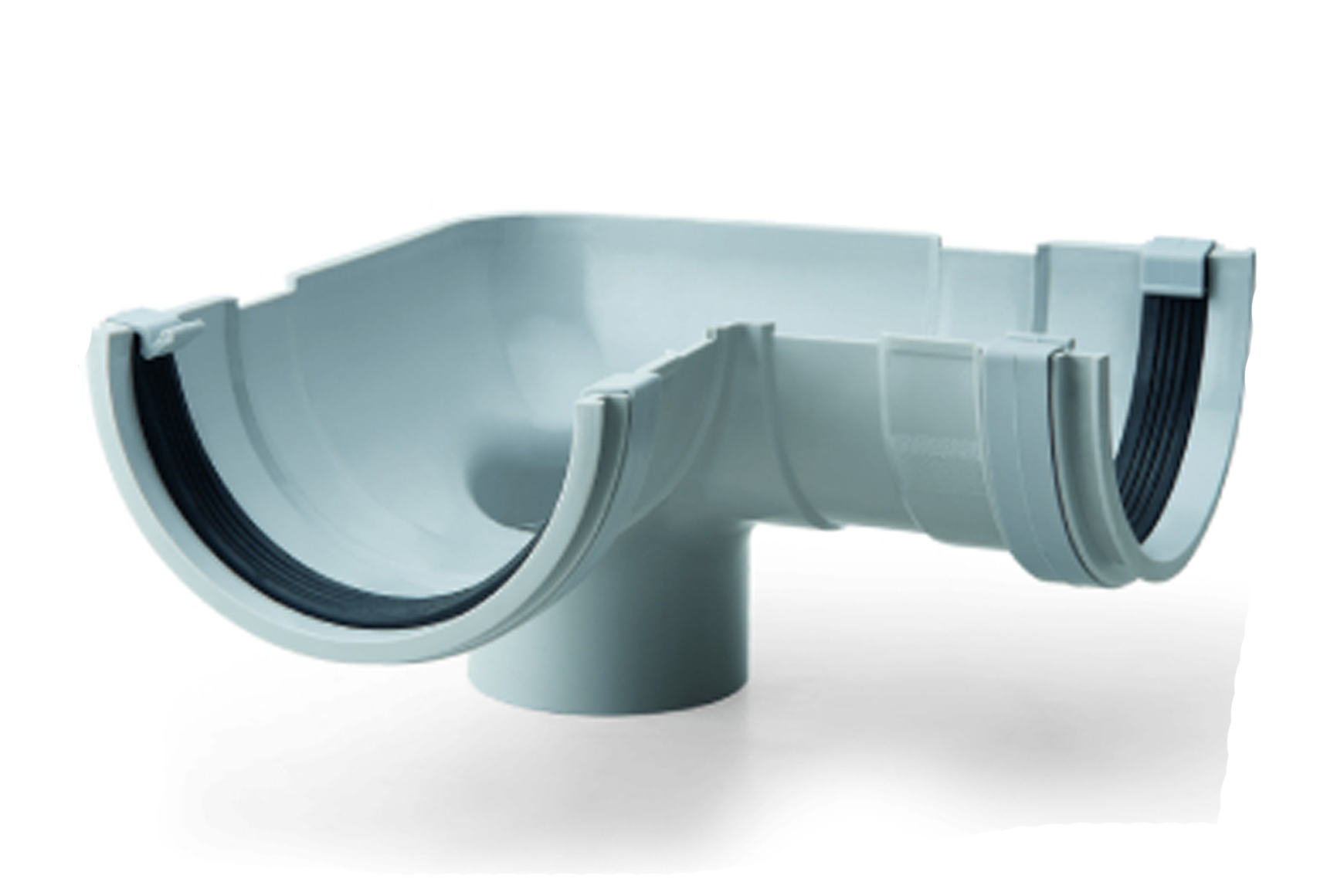

Prince Pipes & Fittings manufactures a variety of pipes and fittings that cater to different industrial applications:

- PVC Pipes: Used in plumbing, drainage, and sewage systems. They are also used in electrical conduit systems and for industrial fluid handling.

- CPVC Pipes: Chlorinated Polyvinyl Chloride (CPVC) pipes are designed for both hot and cold water systems, with applications in industrial and commercial plumbing.

- UPVC Pipes: Unplasticized PVC pipes are used for potable water distribution and industrial fluid transportation.

- HDPE Pipes: High-Density Polyethylene (HDPE) pipes are used in a wide range of industrial applications, including chemical transport, irrigation systems, and drainage systems. They are durable, corrosion-resistant, and flexible.

- Fittings and Accessories: A variety of pipe fittings such as elbows, tees, reducers, and couplings are produced to complement the pipes, ensuring leak-proof, efficient installations in industrial settings.

2. Industrial Applications

Prince Pipes provides piping solutions for various industrial applications:

- Water Supply Systems: For industries requiring water distribution, including factories, processing units, and power plants.

- Industrial Wastewater Management: Pipes are used in industries for handling wastewater, effluents, and sewage disposal.

- Irrigation: HDPE pipes are used in agricultural irrigation systems, vital for farming and agro-processing industries.

- Gas & Fluid Transportation: HDPE pipes are used for transporting chemicals, gases, and other fluids in industrial processes, such as food processing and chemical industries.

- Construction and Infrastructure: Used for potable water, drainage, sewage systems, and plumbing networks in residential and commercial buildings.

3. Technology and Manufacturing Facilities

Prince Pipes operates state-of-the-art manufacturing plants with modern extrusion lines, ensuring the high quality of pipes and fittings. The manufacturing process includes:

- Extrusion Technology: Advanced extrusion lines ensure smooth and precise manufacturing of pipes with consistent quality.

- Quality Control: Adherence to international standards, with a dedicated quality control department to test durability, flexibility, and resistance to chemicals and stress.

The manufacturing plants are strategically located across India to serve a wide customer base.

4. Industrial Certifications & Standards

Prince Pipes & Fittings follows strict compliance with industry standards and regulations, ensuring the quality and safety of their products. Some of the common certifications include:

- ISO Certification: ISO 9001:2015 for quality management systems.

- ISI Certification: ISI (Indian Standards Institute) certified products meeting Indian regulatory standards.

- ASTM Standards: Compliance with international standards like ASTM (American Society for Testing and Materials).

- CPVC & UPVC Standards: Compliance with ASTM, NSF (National Sanitation Foundation), and other global norms.

5. Sustainability in Industrial Applications

Prince Pipes & Fittings places significant emphasis on sustainability and eco-friendly practices. The company ensures:

- Energy-Efficient Manufacturing: Using advanced machinery that minimizes energy consumption.

- Recyclable Materials: Many pipes are made from recyclable materials, contributing to waste reduction.

- Reduced Carbon Footprint: Practices to lower carbon emissions, making production more environmentally friendly.

In industrial applications, products are designed for longevity, reducing the need for frequent replacements and promoting sustainability.

6. Industrial Supply Chain & Distribution

Prince Pipes maintains a strong supply chain network, ensuring products are available quickly and reliably across India. Products are sold through major industrial distribution channels, directly to construction sites, manufacturing units, and infrastructure projects.

7. R&D and Innovation

Prince Pipes & Fittings invests in R&D to continuously improve product offerings and meet industrial demands. Focus areas include:

- Developing new pipe materials with enhanced resistance to high temperatures and chemicals.

- Improving performance and cost-effectiveness.

- Innovating pipe manufacturing to reduce weight without compromising durability.

8. Strategic Growth and Expansion

- Capacity Expansion: Investments to meet growing industrial demand.

- Export Growth: Expanding export business to international markets such as the Middle East, Africa, and Southeast Asia.

- Partnerships & Collaborations: Partnering with global leaders in technology for best-in-class manufacturing practices.

9. CSR and Community Development

Prince Pipes is committed to corporate social responsibility (CSR), with initiatives focused on education, healthcare, and environmental sustainability in communities around its manufacturing units.

Conclusion

Prince Pipes & Fittings Ltd. is a key player in the Indian plastic pipe manufacturing industry, providing a wide range of piping solutions for industrial, infrastructure, agricultural, and residential needs. The company has built a solid reputation through its quality products, state-of-the-art manufacturing, and dedication to sustainability. Its products serve a diverse range of industrial applications, ensuring high performance, durability, and compliance with international standards.